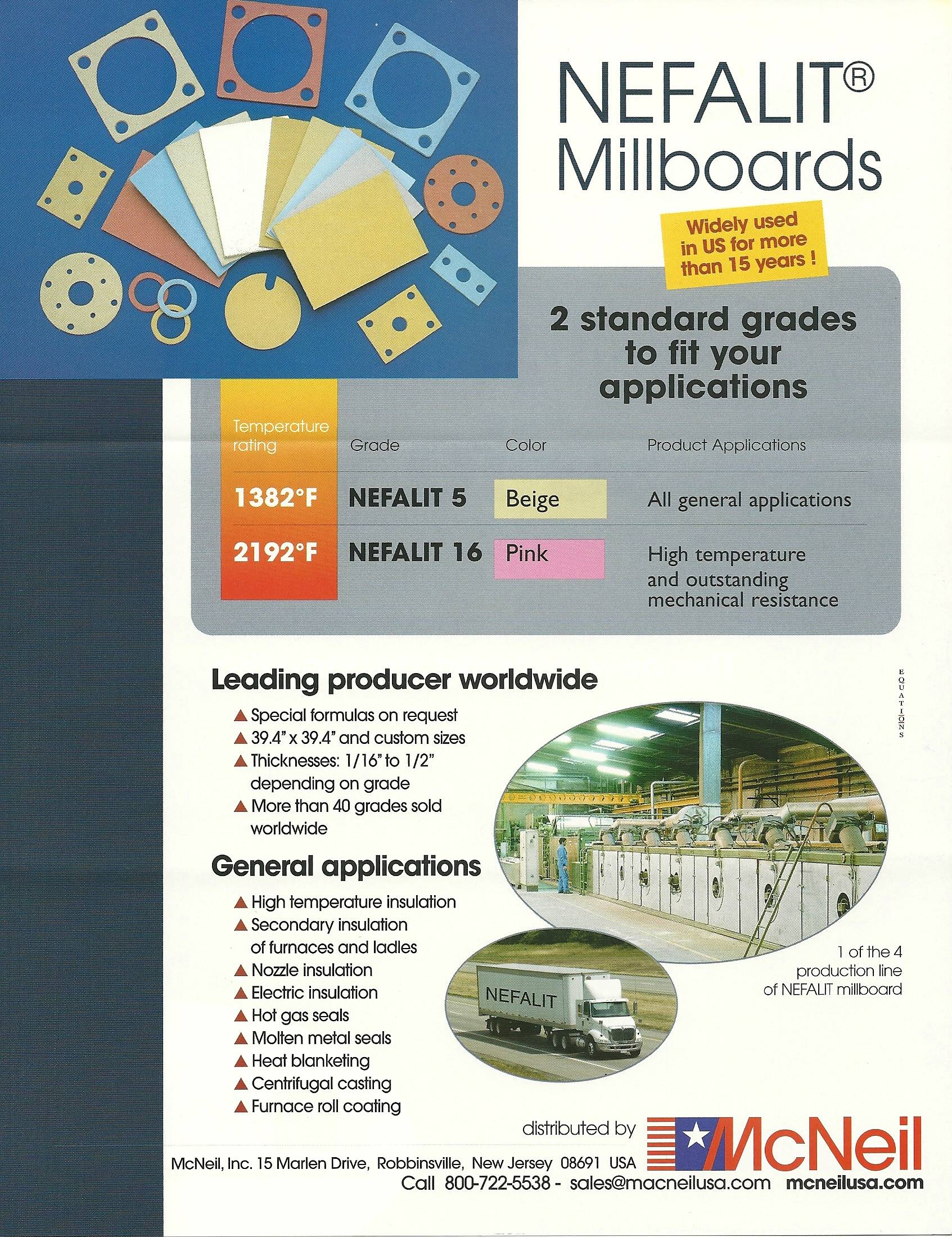

PBI NEFALIT® Millboard

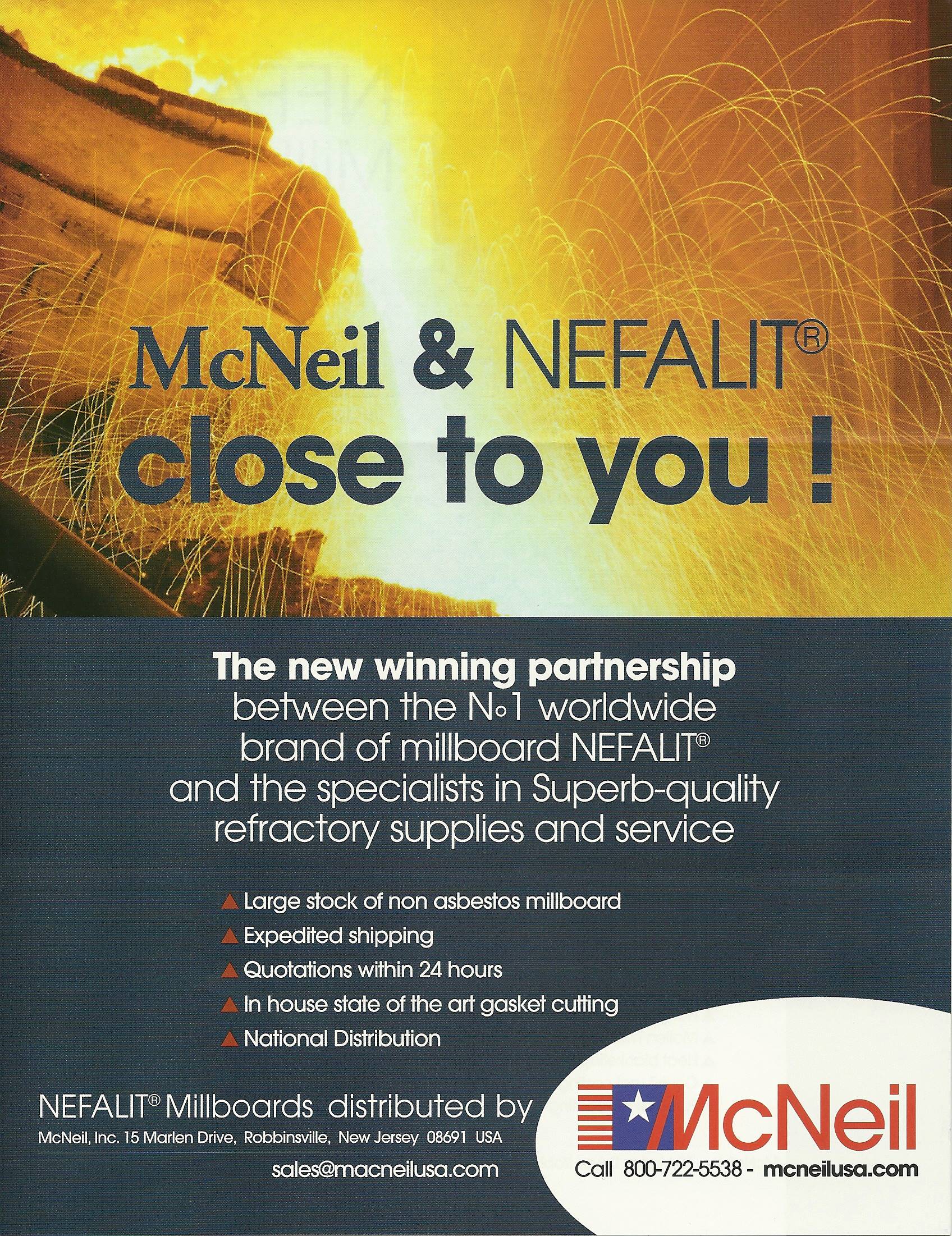

McNeil Is the Exclusive Supplier of PBI NEFALIT Millboard

McNeil is the exclusive distributor for Porteret Beaulieu Industrie (PBI) in the United States. PBI is the world’s leading manufacturer of asbestos-free millboards. We also distribute one of their top products — PBI NEFALIT millboard. This millboard is available in various temperature ranges, and it has been used for more than 15 years by the world’s leading tube casting companies for centrifuge sealing against molten metals for the centrifugal casting process.

PBI NEFALIT Millboard for Centrifugal Casting

The purpose of the seals is to prevent molten metal spillage and keep workers safe. The casting process places stress on the seals, including:

- Compression from the metal cap

- Thermal exposure to molten alloy

- Weight load from the molten metal

PBI NEFALIT millboard is made to endure these conditions. It can be formed into seal rings with an outer diameter between 2 and 25 inches and thickness from 0.25 to 0.5 inches. Compressibility — how soft or hard the material is — may also be important for some applications.

One spun tube needs two seals. The operator removes the end caps and seals when the casting process is complete. These seals can only be used once — no reuse or recycling. The metal tube that was just cast is extracted from the die cast, and the operator cuts the tube ends off for cleanliness.

Discuss Your Molten Metal Project With McNeil Today

As the sole distributor for PBI products, McNeil is the best place to find what you need for centrifugal casting. Contact us today to learn how PBI NEFALIT Millboards can help your project.

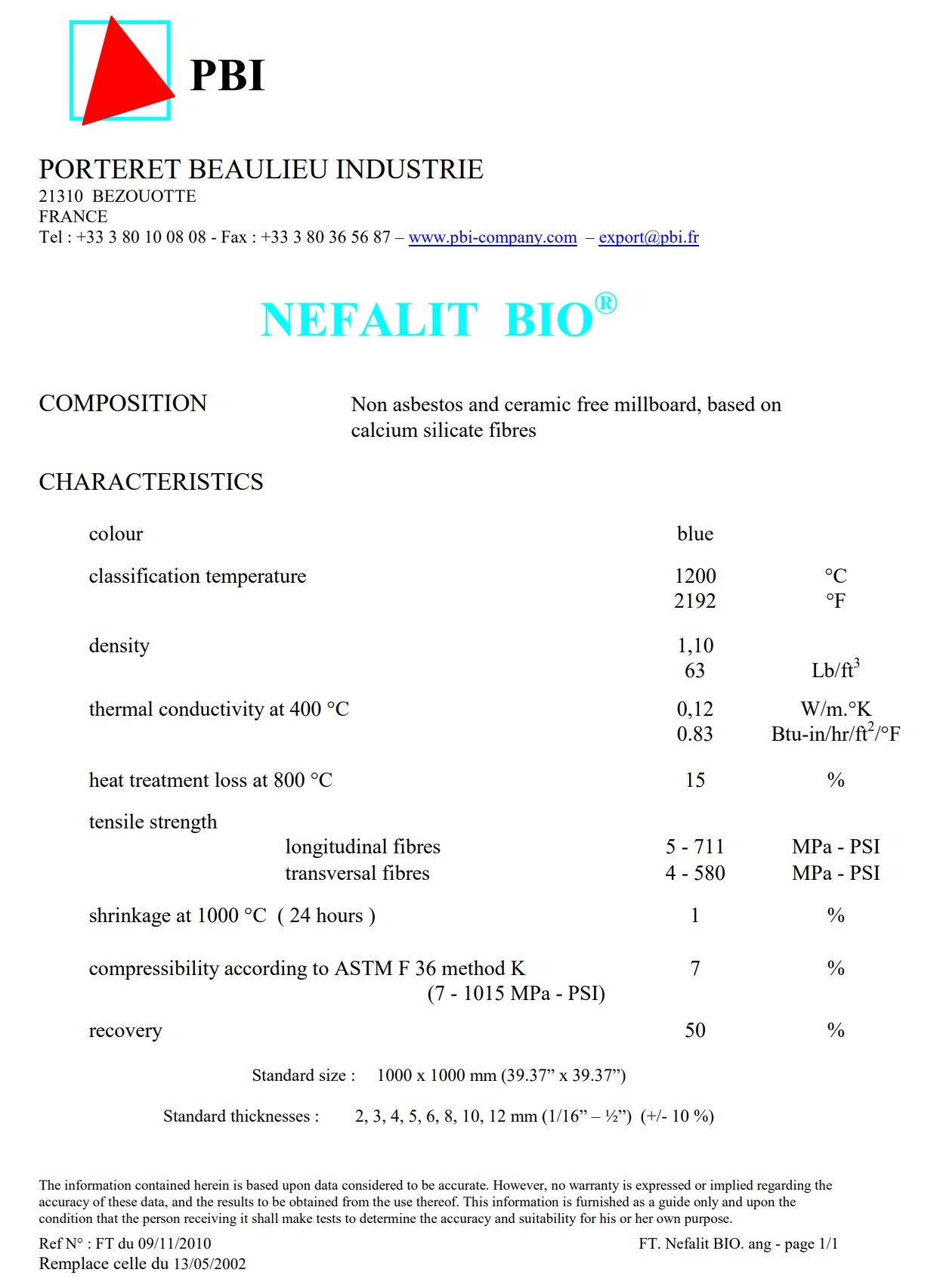

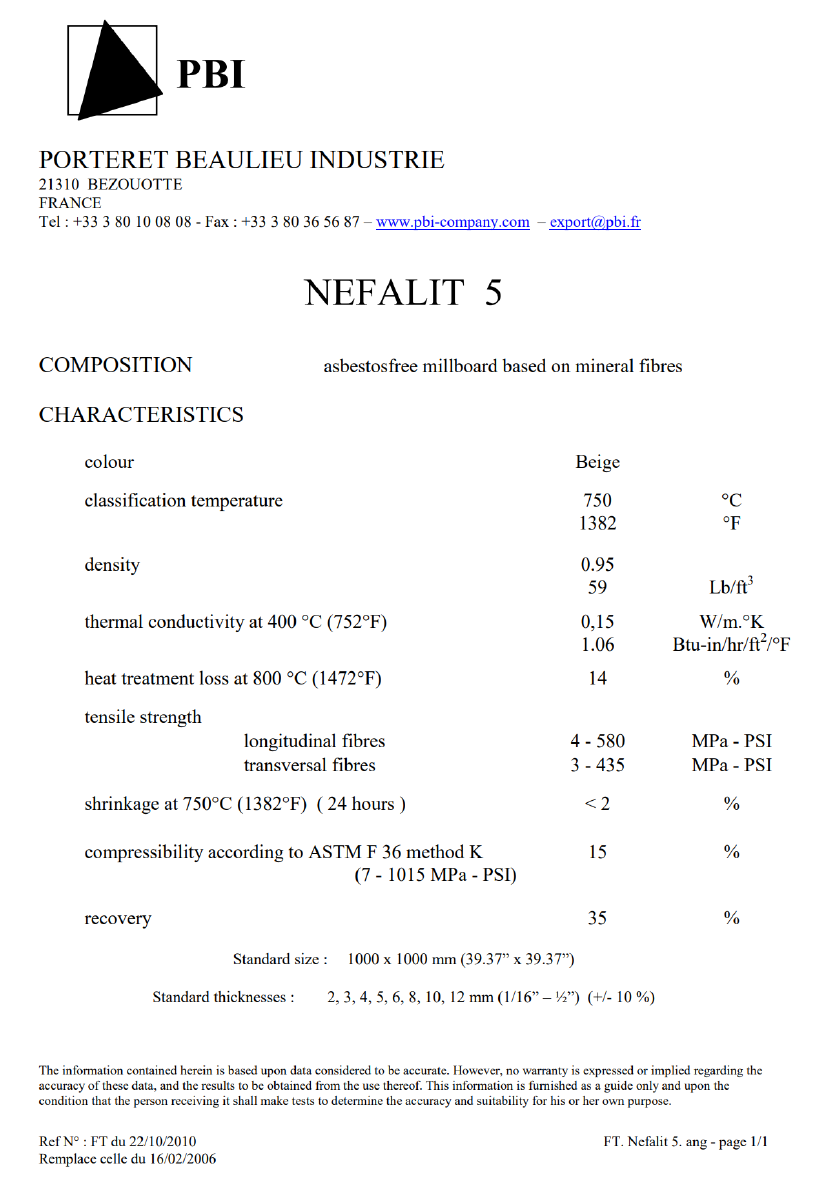

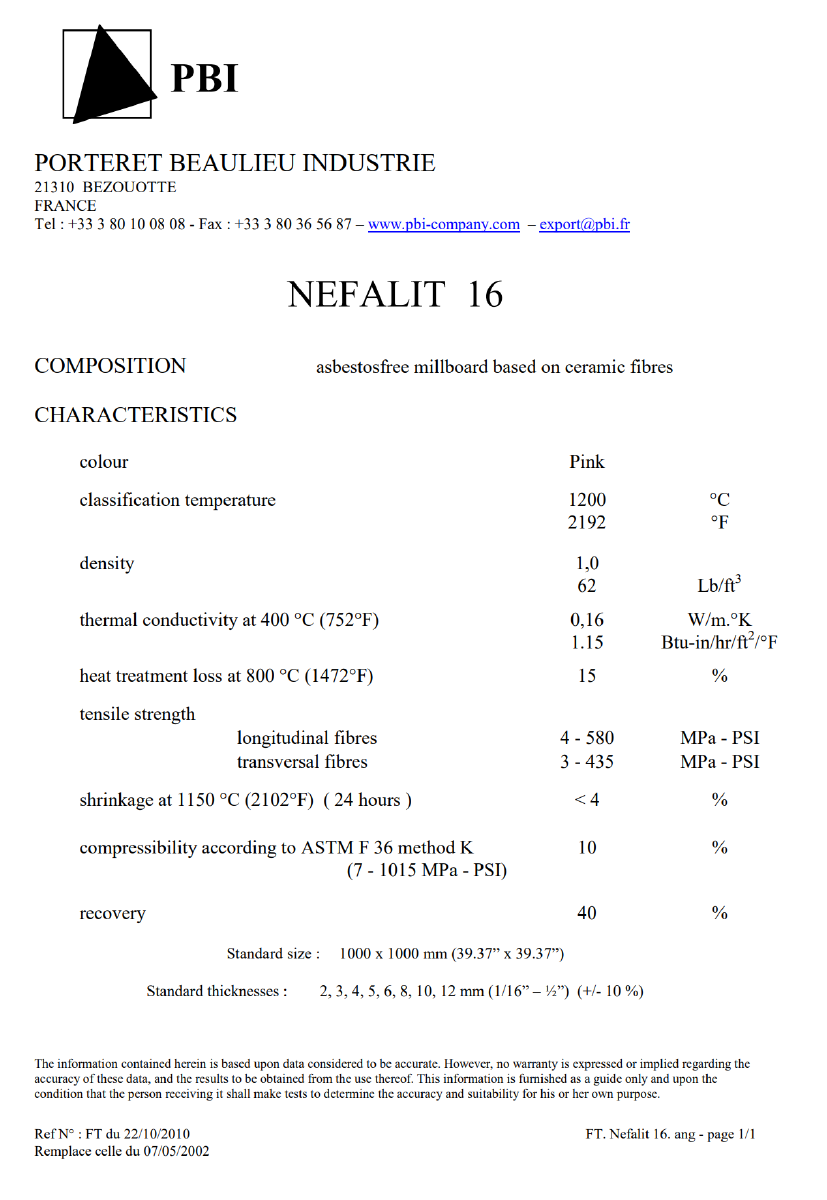

Manufacturer’s Specifications

Click image to enlarge