Ceramic fiber offers high tensile strength and the ability to seal and insulate, even at high temperatures, making it invaluable in the construction industry. McNeil supplies this versatile product in various forms, including ceramic fiber boards, felts, papers, blankets and textiles.

What Are Ceramic Fiber Boards?

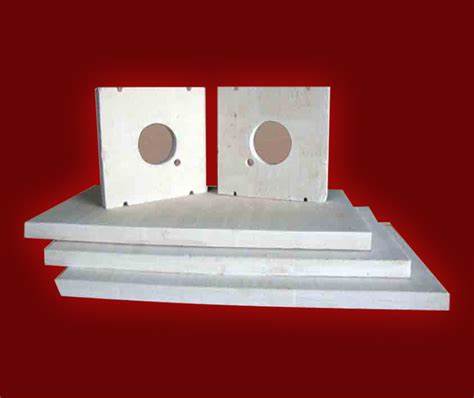

Ceramic fiber boards offer rigid, self-supporting stability while remaining flexible and lightweight. Like all ceramic fiber materials, boards are manufactured from a superheated mixture of aluminum and silicon that is separated into strands and woven together. The result is a high-density solid material that provides outstanding thermal resistance.

These heat-resistant boards are made by vacuum pressing the ceramic fiber material in a wet forming process. This allows ceramic fiber boards to be produced according to precise manufacturing specifications. Ceramic fiber board options include thickness, density, size and temperature rating.

What Are Ceramic Fiber Boards Used For?

Because of their superior heat resistance properties, ceramic fiber boards have many uses in the construction industry. They offer a practical alternative for many applications that once relied exclusively on fire bricks. Since the material can be machined, it is highly adaptable and easy to install. It is ideally suited to backing up or facing hot installations, including:

- Chimney linings

- Boiler walls

- Heat shields

- Furnace and kiln linings

- Gaskets and seals

- Combustion chambers

Other heat-resistant materials are often used to back high-temperature ceramic fiber boards, including lower-temperature ceramic fiber boards or ceramic fiber blankets. These form a solid line of defense in many settings where extreme heat is a factor.

The Advantages of Ceramic Fiber Boards

Ceramic fiber boards have many excellent characteristics, providing significant advantages over other materials in particular settings. These include:

- High temperature stability: The material displays minimal variation in performance over a wide range of temperatures.

- Low thermal conductivity: The inability of ceramic fiber to conduct heat efficiently makes it an excellent insulator.

- Uniform density: Ceramic fiber board is manufactured to precise specifications, ensuring properties are consistent on every part of the board.

- Excellent resistance to thermal shock: The material is able to withstand rapid temperature fluctuations.

- High chemical- and corrosion-resistance: Ceramic fiber boards are suitable for use in environments where corrosive or chemical processes are used.

- Low heat storage: Ceramic fiber boards act as a barrier that slows heat transfer from one side to the other.

- Lightweight: The material is easy to transport and handle.

- Machinable: Ceramic fiber boards are easy to shape to ensure an accurate fit.

- Tolerance for dampness, splashes and steam: Wet ceramic fiber board returns to its original condition once it is dry.

McNeil Supplies Ceramic Fiber Board Solutions for Any Project

McNeil has been in the custom heat-management service industry for over 80 years. You can rely on us to provide quality materials, fast turnarounds and custom solutions. We stock ceramic fiber boards suitable for a variety of sealing and insulating applications. Contact us today to get a quote or find out more about using ceramic fiber boards in your next project.

Contact Our Team