Where Are Fiberglass Gaskets Used?

Fiberglass is a highly durable, heat-resistant sealant. Its flexibility and versatility make it the premier choice for sealing and high-temperature applications across dozens of industries. Gaskets are subjected to extreme conditions — failure can be catastrophic. If you want to ensure safety and efficiency, using one of the many fiberglass sealing options helps protect your product, employees and facility from harm while maximizing productivity.

Explore the various fiberglass products and their uses as gasket materials to find the best fiberglass gasket for your needs.

Fiberglass Cloth

Fiberglass cloth is a woven composite fabric made from fiberglass strands. Using fiberglass makes this material extremely versatile — its flexibility, durability and strength make it applicable across many industries. Fiberglass’ heat and chemical resistance make fiberglass cloth extremely popular for dozens of uses. Thanks to its high strength-to-weight ratio, you’ll see fiberglass cloth used in protective gear like helmets and body armor, surfboard manufacturing and crafting.

With so many uses and benefits, fiberglass cloth is a popular choice for many large industries. Here are some industries that commonly use it in their operations:

- Construction: Fiberglass cloth is employed in the construction industry for reinforcing materials called fiberglass-reinforced plastic (FRP) composites. FRP composites are used to build lightweight, sturdy structures like aircraft parts, boat hulls and car bodies. Additionally, fiberglass cloth is used to reinforce concrete, preventing cracking and enhancing its strength.

- Manufacturing: Another common application for fiberglass cloth is insulation product manufacturing. Fiberglass provides excellent acoustic and thermal insulation in commercial buildings, homes and industrial settings. It improves your energy efficiency and creates a comfortable home or workspace.

- Automotive: The automotive industry uses fiberglass cloth for producing durable parts like hoods, bumpers and interior panels. Fiberglass cloth’s lightweight properties contribute to fuel efficiency while maintaining structural integrity. Additionally, the automotive detailing industry uses it for color contrast and rust resistance.

- Marine: Fiberglass cloth is extremely popular in the marine industry for its high rust and corrosion resistance. Fiberglass is also used in the manufacturing of boat hulls, liners, decks, consoles and more. Even water tanks and pipes commonly incorporate fiberglass into their construction.

- Aerospace: Fiberglass cloth is essential to the aerospace industry. Its lightweight, heat-resistant nature makes it ideal for aerospace test equipment, enclosures and ducting. Fiberglass fabric is also found in jet engines and aircraft interiors.

Fiberglass Tape

Fiberglass tape is made from many twisted fiberglass strands. These fibers are woven together to create highly durable tape. Selvage edges prevent the tape from unraveling. Its strength helps it withstand severe stressors, and its self-adhesive properties make it a convenient, lasting tape for many uses.

There are numerous practical applications for fiberglass tape. Here are some of the industries that take advantage of its beneficial properties:

- Construction: Fiberglass tape is often used for drywall finishing and repairs. When embedded in the joint compound, it reinforces seams between drywall sheets — this prevents cracks and provides a smooth surface for wallpapering or painting. Fiberglass’ moisture resistance makes it useful in damp-prone areas like kitchens and bathrooms.

- Electrical: Fiberglass tape plays a critical role in electrical insulation. Its nonconductive properties make it ideal for wrapping and insulating cables, wires and electrical components. Wrapping components with fiberglass tape helps ensure safety and efficiency in electrical systems.

- Automotive and aerospace: Fiberglass tape is used for composite material reinforcement in both the automotive and aerospace industries. Fiberglass tape helps enhance structural integrity while keeping components’ weight to a minimum for improved performance and fuel efficiency.

- Plumbing: Fiberglass tape works well for repairing leaking pipes and fittings. When coated with adhesive, fiberglass tape is a reliable solution for temporarily sealing leaks until more permanent repairs can occur.

Fiberglass Rope

Fiberglass rope is a woven, nonflammable silica yarn used as sealing and gasket material. Fiberglass rope’s strong, lightweight properties make it useful in many industries across applications, including:

- High-temperature sealing: Fiberglass is heat-resistant and nonflammable, making it a valuable tool for high-temperature sealing and insulation. Fiberglass rope is used to create tight seals in boilers, ovens, furnaces and wood-burning stoves. This prevents heat loss and ensures efficiency.

- Automotive: In the automotive industry, fiberglass rope is employed as a gasket material in exhaust systems and engines. Its ability to withstand extreme temperatures and resist chemical damage makes it ideal for intense environments.

- Industrial: Industrial settings also use fiberglass rope for a variety of applications. One primary use is sealing doors and access points to prevent heat or cold from escaping and control temperature.

- Mechanical and engineering: Fiberglass rope’s durable sealing properties make it an effective protectant against debris, leaks and dust in mechanical and engineering applications.

Fiberglass Tadpole Tape

Fiberglass tadpole tape — or tadpole gasket tape — is a specialized sealing material designed to provide a high-pressure, high-temperature seal for many industrial applications. Tadpole tape gets its name from its unique appearance — its round section and thin tale resemble a tadpole. The bulbous section of tadpole tape is typically made from fiberglass rope to provide advanced heat resistance and compression capabilities. The tail is made from more flexible materials like neoprene, rubber or silicone.

Fiberglass tadpole tape conforms to irregular surfaces. Compressing the bulb creates an insulating seal fixed in place by the tail. It’s used for a few different applications:

- High-temperature: Fiberglass tadpole tape’s flexibility and ability to withstand high pressure and thermal cycling make it popular in critical sealing applications where traditional gaskets might fail. Its extreme temperature resistance lets it work well in boilers, furnaces, high-temperature piping systems and industrial ovens.

- Sealing: The energy, automotive, manufacturing and aerospace industries use fiberglass tadpole tape where reliable sealing against liquid, heat and gas is essential for ensuring safe and efficient equipment and machinery operation. Its unique design and high-performance properties make fiberglass tadpole tape valuable for sealing applications.

Fiberglass Thread

Fiberglass thread is formed by stringing together fiberglass filaments. These filaments usually have an added coating to reduce friction and improve functionality. Stringing fine fiberglass fibers together makes a thread with superior heat resistance and high tensile strength. Fiberglass thread is used in the following applications:

- Composite construction: Fiberglass thread helps reinforce materials like FRPs and creates strong, lightweight structures for the aerospace and automotive industries.

- Fire-resistance: Using fiberglass thread can help improve the fire-resistance of fabrics, protective clothing and filtration systems.

- High-temperature needs: Heat-resistant applications will use fiberglass thread in thermal insulation materials for furnaces, automotive components and industrial ovens.

Use McNeil for All Your Fiberglass Textile Needs

With over 80 years of industrial heat-management construction and installation experience, you can trust McNeil to deliver the lasting, quality materials you need. Our superior fiberglass and silica textiles provide unmatched protection and sealing in high-temperature environments. McNeil’s fiberglass sleeves, cloth, rope and tape all display the low conductivity, high mechanical strength and excellent spark resistance needed to withstand environmental stressors. If you’re interested in our fiberglass textiles or need our repair and installation services, contact us online today.

Should You Replace or Fix Your Commercial Boiler?

The boiler inside your business needs to be in working order. Pressurized equipment should be monitored to ensure work environments are safe for employees and liquids can be heated accordingly.

If you’re a facility manager, you’ll need to act on commercial boiler maintenance and repairs. Is it better to restore or replace an industrial boiler? The answer will depend on several factors.

Consider the Age of the Boiler

Industrial boilers consume a great deal of energy — the technology runs around the clock to keep your operations moving. It’s important to understand boilers will require replacement at some point. An industrial boiler can last upward of 20-30 years when facility managers schedule regular maintenance.

This estimate is not a guarantee. Expect an increase in maintenance and repair needs for a boiler once the installation approaches or surpasses the manufacturer’s rated service life.

Recurring Repair Needs

Frequent repairs add up. Your business may benefit from a complete boiler replacement when the same issue presents itself repeatedly and your old boiler declines in efficiency. Review maintenance records for your boiler assembly to see whether complications derive from the same components or are widespread.

You may find your industrial boiler starts leaking or grows louder toward the end of its life expectancy. Facility managers can do their part by looking out for buildups and clogs within pipes. How long boiler pipes last will depend on how often they are serviced and environmental conditions. Some areas of a boiler you could see deteriorate are the burner, heat exchanger, combustion chamber and system controls.

Review Boiler Fuel and Energy Costs

Looking at energy use and fuel demands from the time a boiler is installed to the present day is useful for figuring out if you should repair or replace technology. Keep track of facility fuel consumption rates and energy bills to see if there is room for improvement.

Fuel Type Matters

The type of fuel your system needs and how much your plant uses will make it easier to see if repairing or replacing your technology is productive.

Most industrial boilers are powered by coal, oil or natural gas. Coal is becoming less common in the industrial field due to environmental factors. Some businesses choose to integrate boilers that run on biomass, like corn husks and wood chips, to minimize their carbon footprints.

When your industrial boiler runs on a more expensive fuel variety and breaks down often, it’s worth exploring your options for a replacement assembly. Estimating the amount of fuel you’ll use in the future is effective in making the right decision for your plant.

Options for Retrofitting

Maybe your industrial boiler is a few years old but fuel costs are increasing for your build. Facility managers might think about retrofitting their units. This involves changing boiler parts to support a fuel type different than what was intended by the manufacturer.

You could potentially save money by modernizing an industrial boiler with updated parts. Make the transition from solid, liquid or natural fuel to another variety that makes sense for your budget.

Evaluate Facility Safety Concerns

Look out for your employees when deciding to repair or replace an industrial boiler. Pressurized vessels are dangerous when maintenance intervals are missed. Most boilers feature a pressure relief valve, but there is a chance an unchecked assembly could wear out to the point where superheated steam causes an explosion.

Only authorized personnel should make changes to an industrial boiler. A qualified professional should check for leaks, verify gauges work and monitor performance. Attending to a cracked boiler or rusting surfaces with an experienced technician is essential for creating a safe workplace. The technician you rely on for system inspections should inform you when adding a new unit to your plant is the best course of action.

Boiler Problems to Address Quickly

The following details describe situations when an industrial boiler may fall short of compliance standards:

- Surges and pulsations: There is a chance the burner or combustion fan is disrupting the flow of fuel and air throughout the boiler assembly.

- Boiler stops suddenly: This indicates safety controls have kicked on due to faulty operation controls. Safety features stop the boiler from running to reduce the chances of an accident.

- Temperatures skyrocket: A qualified technician may find a boiler’s operating conditions unsafe because of decreased water levels or poor water quality.

Investigate Boiler Configuration and Efficiency Issues

A popular boiler setup involves having two units in a facility. One boiler is the primary assembly and carries the heating load while the opposite boiler is for emergencies. This configuration works well for heating and power, but it is far from the most efficient.

Boiler technology is capable of changing its firing rate to accommodate different loads. Once a load plummets below an assembly’s minimum rate, it’s common for the unit to power down. The cycling process puts additional stress on boiler parts when temperatures fluctuate. A facility manager might think about adding several small boilers in a plant and configuring them to turn on with increasing loads.

This setup keeps professionals ready for emergencies and eliminates the need for cycling. Improve efficiency and system reliability, as the shutdown of one boiler will not influence heating capacity.

Update Your Boiler for Maximum Productivity

A boiler’s efficiency level is typically lowered the longer the unit is in use. Scale inevitably builds up on burner surfaces, and repairs become more of a short-term fix. Just because a boiler is in working condition does not mean you’re getting the highest level of performance out of the installation. Think about replacing an industrial boiler when there is evidence performance levels are not what they used to be.

Choose McNeil Company for Boiler Installation and Repair Services

The experts at McNeil have been serving customers in the metal, petroleum and chemical industries for over 80 years. Whether you’re interested in upgrading from your existing boiler or you could use assistance with a repair, know we’re here for you with locations in New Jersey, Florida and Virginia.

We work on industrial boilers of all sizes and varieties. There’s a reason why industrial organizations trust us to come up with solutions for facilities — our customers are our top priority, and we won’t rest until you’re satisfied with our services. Ask the McNeil team for a quote to hear more about pricing details.

How Do Commercial Boilers Work?

A commercial boiler contains water and transfers heat from a fuel source, such as gas, oil or coal, into steam. The steam is piped to a specific location, allowing it to run equipment, sterilize, steam-clean or provide heat. These boilers are essential to transfer heat energy from one place in your business to another, allowing everything to operate efficiently.

Some commercial boilers use an open system, which allows the steam to return to water form and be reused for different functions. Other boilers run on a closed system, meaning they don’t return the steam to water where it can be reused.

Below, you’ll learn more about how industrial boilers work, the types of boilers and other high-pressure steam boiler basics to help you operate your building’s equipment effectively.

Parts of a Commercial Boiler

Generally, commercial boilers contain the same parts and components essential for effective heating. Some of the standard components of a commercial boiler include:

- Burner: The burner is responsible for providing the flames that heat the water in the vessel. The burner helps create a mixture of fuel and oxygen, allowing the fire to burn efficiently and consistently.

- Combustion chamber: This is the area in the boiler where fuel burns to assist with heating the water. The combustion chamber is where the burners are located and is designed as a secure and safe location for the combustion of volatile fuel at high temperatures. Typically, combustion chambers are made from steel, cast iron or other heavy-duty metals.

- Heat exchanger: This vital component transfers the burners’ heat to the water, allowing it to create steam. Heat exchangers are usually made of copper, steel, cast iron or heavy-duty metal.

- Exhaust stack: This component is also called the flue. It consists of a series of pipes that carry exhaust fumes away from your facility’s interior and outside. An exhaust stack must be carefully constructed to ensure toxic fumes, such as carbon monoxide, are safely removed from your facility’s interior.

- Controls: System controls are an essential part of a commercial boiler, allowing you to set the water temperature, internal pressure, ignition, and fuel and air supply mixtures. You can control how often your burner fires, the rate at which your fuel is used and the quality of the fuel and oxygen mixture. The controls have safety features, allowing you to ensure your system stays operational.

All of these components are essential to a boiler, allowing it to operate safely and efficiently within your business. Without one of these components, your boiler couldn’t provide heating or other essential functions to your commercial enterprise.

How a Commercial Boiler Operates

There are different commercial boilers you can use. However, most boilers work similarly, using burning fuel or electricity to create heat and provide a hot water supply to a building. Depending on the type of system, the boiler may produce steam or hot water, which is then circulated in the pipes within a commercial facility.

Electric coils or fuel burners create heat in a boiler, which is transferred to the water from the heat exchanger. The hot water or steam travels through pipes within the building to the designated area. The water or steam enters the radiators of other heating systems in the building to disperse the warmth, allowing you to keep a space at your desired temperature.

The end goal of a commercial boiler is to produce consistent heat within a commercial building, whether it’s an office, medical facility, apartment complex or school.

Commercial Boiler Maintenance and Safety Tips

Remember that boilers contain steam or hot water under high pressure, so boiler maintenance is essential to sustain your boiler’s life span. You must take the proper steps to ensure your boiler stays clean and works correctly.

Hot water or steam leaks can cause significant damage or injuries. In some cases, boilers can explode when not adequately maintained, creating the potential for severe injuries or death.

You can follow some of the tips below to keep your boiler properly maintained:

- Ensure operators are aware of boiler regulations: Boiler operation regulations vary by state. For example, most states require your boiler to be inspected yearly, but some don’t. You should make any rules or regulations available to anyone who comes in contact with the boiler to ensure they follow protocol.

- Train everyone on boiler safety: While boiler explosions are rare, they can still happen. It’s essential to train operators on boiler safety, so they know what to look for, including temperature and water or pressure levels. They should also be able to spot signs of corrosion to ensure it’s handled correctly and quickly.

- Keep the boiler room clean: An unorganized or dirty boiler room can create a hazard. You also don’t want to store any flammable materials in a boiler room for the same reason. You should also consider restricting access to the boiler room to technicians and operators who have training in basic boiler safety so you don’t risk injuries and the area stays clean.

- Schedule time to make repairs or upgrades: A boiler requires repairs and upgrades throughout its lifetime. You may need to schedule some downtime for these repairs or upgrades, which means you can use rental boilers while yours is being repaired or upgraded. Even with a rental boiler, you’ll still need to inspect it regularly to ensure everything is working.

- Hire a professional: You should hire a professional to conduct your maintenance and repairs to ensure your boiler is taken care of properly. Professionals have the experience and knowledge to perform high-quality maintenance and repairs when necessary efficiently.

Schedule Boiler Installation or Repair With McNeil

If you need professional help with boiler installation or repairs, McNeil is here to help. We offer high-quality boiler installation services to help you install complex equipment that’s efficient and safe for your commercial processes.

We also offer boiler repair services when your boiler needs maintenance or repairs for specific components. We can work on all commercial boilers, whether you use electricity, gas, hot water or steam.

You can utilize our repair and installation services from any of our Florida, Virginia, or New Jersey facilities. When you choose us, you can rest assured we’ll exceed your expectations and help you keep your commercial operations functional.

Contact us today to learn more about our boiler services or get a quote!

When Should You Replace Refractory Materials?

Refractories are vital components in boilers and furnaces. These linings of brick and high-temperature cements act as a protective lining against the ongoing processes within a boiler’s combustion chamber, including destructive heat, abrasion and corrosion. Installing refractories correctly is essential for ensuring efficient and safe operation in both industrial and commercial boilers. However, just as important as proper installation is proper maintenance, which includes knowing when to replace key refractory materials.

What Causes Refractory Lining Wear?

Like the tires of a car, refractories wear out over time due to the damaging environment in which they operate. While wear can be minimized by following proper heat up and cool down procedures and performing simple maintenance, the refractory lining can crack, erode or otherwise get damaged for many reasons. Some of the most common causes of refractory lining wear include the following:

- Abrasion: Abrasive products like fuel, ash and other particles are often used in boiler systems. Like a sandblaster, these products will wear away at the refractory lining over time.

- Thermal cycling: Boilers and furnaces cycle in their heat production, generating massive amounts of heat up to 3,000°F before cooling off. Refractory linings, therefore, undergo the same thermal cycling, causing the refractory materials to expand and contract continuously. This results in materials such as firebricks, gaskets and fiberglass insulation degrading over time. In some cases where there is a sudden massive change in temperature called thermal shock, the rapid expansion or contraction of the material will cause more drastic and immediate damage to the refractory lining.

- Corrosion: The lining of a refractory can chemically react with materials and byproducts from the boiler. These chemical reactions can cause the refractory materials to soften or glass over, eventually resulting in surface failure.

- Erosion: Moving liquids like slag and molten metal in a boiler create a washing action against the refractory lining. Over time, this movement of liquid can erode the refractory lining, leaving the materials more prone to destruction from other causes like abrasion and corrosion.

- Mechanical wear: Moving equipment and parts in the boiler can place stress on the refractory lining, resulting in wear. Continuous mechanical wear can damage the structural integrity of the refractory lining.

- Improper materials: Sometimes, refractory materials wear down more quickly because the wrong materials were used to build the refractory. The material may not be suitable for the type of fuel being burned or the environment needed for the boiler and fuel combustion process.

- Improper installation: In some instances, a refractory owner or their hired installation team will rush the refractory installation or repair process, resulting in an improper installation. Missed or shortened steps in laying refractory bricks, choosing materials or letting the setup cure can all result in significant structural problems for the refractory.

- Improper maintenance: Another cause of refractory failure is human error in the form of improper maintenance. For example, refractories will often form “good cracks” as part of the natural cool-down process, which disappear during the heat-up process. Filling in these cracks unnecessarily can result in shell bulge and material wear since the materials will naturally expand again.

Refractory failure is one of the leading causes of boiler failures and inefficiencies, and refractory lining wear can also result in damage to other components of the boiler, such as the boiler tubes, burners and other systems. This extensive potential damage is the reason why boiler owners need to be aware of the causes of wear and implement a maintenance procedure to identify and handle wear as soon as it happens.

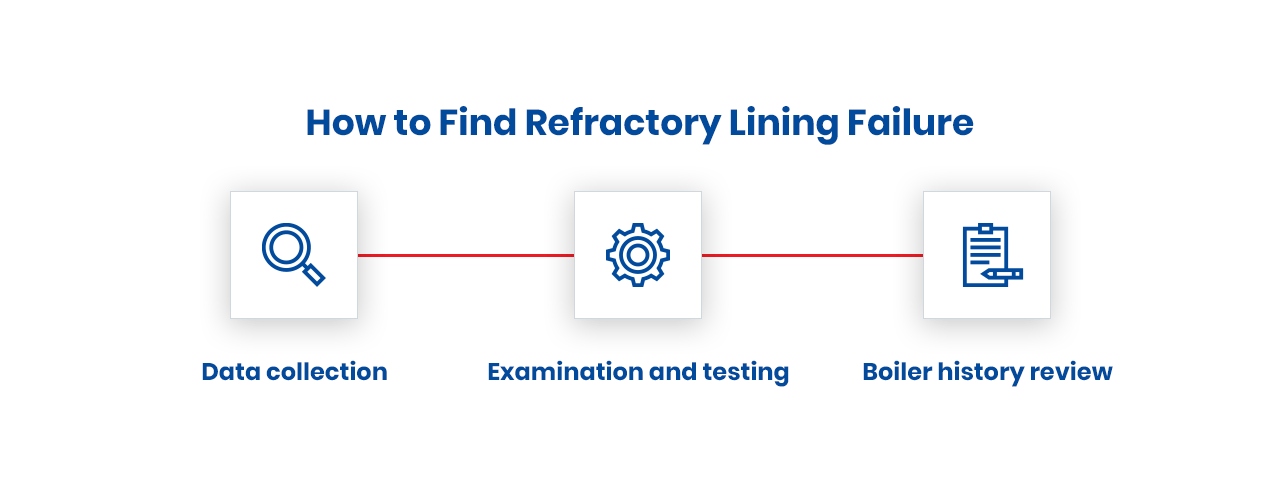

How to Find Refractory Lining Failure

Discovering the cause of a refractory material failure is a complex process that requires expert repair and installation personnel working in tandem with your internal team. While the process itself will look different depending on the specific qualities of your boiler plant, the process generally follows the steps below:

- Data collection: To start, have your repair crew work with your internal team to collect as much information about the refractory as possible, including details about performance changes, chemical compositions of boiler fuel being burned and material samples of slag and ash. In addition to this information, provide as much detailed information about the installation of the refractory, such as the composition and manufacturer for the materials used, the condition of the material during installation and all installation procedures and timelines used.

- Examination and testing: After collecting samples and data, a repair crew can analyze the information to determine the likely cause of wear and how to handle it. Experts will typically look for evidence of the above-listed causes of refractory lining wear to determine the primary culprits. The team will also likely run samples through various tests to verify the strength of refractory materials and the type of environment the refractory operates with.

- Boiler history review: The repair crew will also take a look at the details of a boiler refractory’s history to glean clues as to the types of repairs and replacements needed. This often involves analyzing the details of the refractory installation to determine if any errors could have compromised the refractory’s integrity. They will also take a look at the recent boiler and refractory services to determine if any changing boiler conditions or faulty repair operations may have affected the refractory.

Once the repair team has completed these steps, they will typically know the cause of the wear. From here, the team should be able to make a recommendation for the repair, whether it is replacing an insulation board or redoing the installation completely.

Maintenance Schedule for Refractory Lining

Like any essential equipment, refractory linings should undergo regular maintenance to ensure optimal operation and longevity — without proper maintenance, refractory lifespans can be reduced by 50% or more. This means that your company needs to create a thorough maintenance schedule for your refractory lining. But when should you schedule maintenance for refractory components?

The truth is that there is no one-size-fits-all approach to scheduling maintenance for refractory lining. Different types of materials and equipment require different maintenance schedules — when to replace ceramic fiber will differ from how long a gasket will last in the same environment. Depending on what materials and components are used in the refractory lining, maintenance schedules will vary widely from boiler to boiler.

The best way to set a maintenance schedule is to have a refractory engineer perform an inspection similar to the process outlined in the previous section. Using the information gathered, they can then create a custom maintenance plan for your equipment.